Application

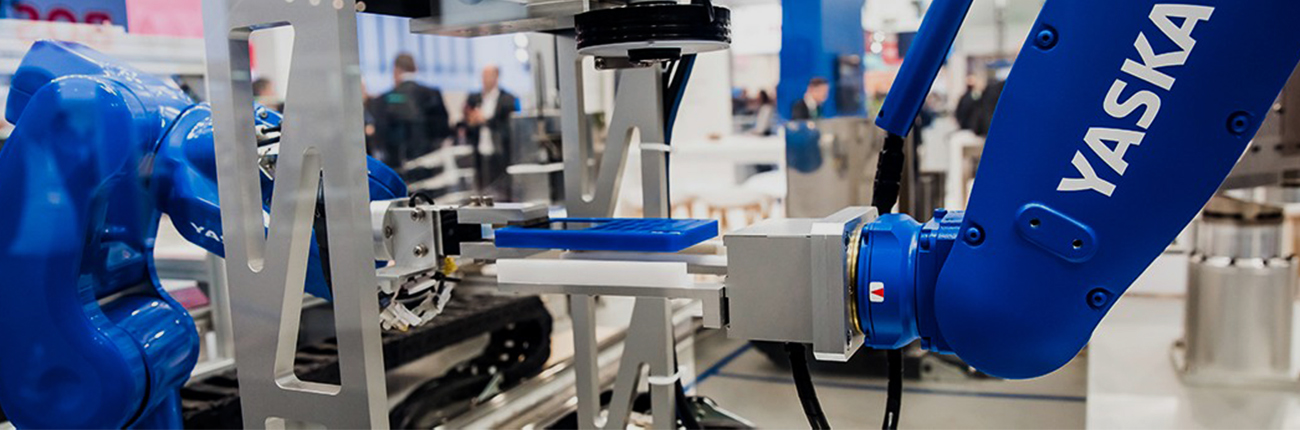

The Yaskawa Human Collaborative 10 (HC10) Robot is a capable, safe, affordable, and easy to use Collaborative Robot that delivers industrial robot performance and safety. HC10 is for customers that need to automate tasks that require a robot to work near humans, where space is limited, and where the robot may need to be frequently redeployed.

For more information click Collaborative Robot.

Welding

Arc Welding

The Global Leader in Robotic Arc Welding, Arc welding is the core of our company. Over three decades, Yaskawa Motoman has developed more welding robots, sensors, software and positioners than any other company. Our welding process knowledge and path control leads the industry – resulting in expert support and robotic welding technology that tackles your biggest challenges.

With our comprehensive line of arc welding robots, integrated power sources, torches and peripherals, and our extensive family of fully integrated ArcWorld welding cells, we provide building block solutions that are simple to integrate and operate.

Spot Welding

Fast cycle times, efficient space utilization and simple operation are “must-have” requirements for spot welding operations. Yaskawa has developed unique solutions that maximize the benefits automation brings to the process.

As a world leader in robotic welding, Yaskawa Motoman offers spot welding robots with a broad range of payloads, reaches, integrated spot harnesses and servo-controlled spot guns. We have collaborated with automotive OEMs to create innovative robots to improve body shop productivity. Our SpotWorld® platforms have helped manufacturers improve productivity and reduce time to market.

Spot Welding

Fast cycle times, efficient space utilization and simple operation are “must-have” requirements for spot welding operations. Yaskawa has developed unique solutions that maximize the benefits automation brings to the process.

As a world leader in robotic welding, Yaskawa Motoman offers spot welding robots with a broad range of payloads, reaches, integrated spot harnesses and servo-controlled spot guns. We have collaborated with automotive OEMs to create innovative robots to improve body shop productivity. Our SpotWorld® platforms have helped manufacturers improve productivity and reduce time to market.

Handling / Assembly

Our unique approach to material handling solutions is founded on two core principles : exceptional design and optimal configuration. We start with an industry-leading range of robots, controllers and accessories all engineered for maximum performance. Our specialists then work with customers to determine the best combination of components for their specific needs, including analyzing parts and processes.

For more information click Handling/Assembly Robot.

Packaging / Palletizing

Packaging

Our integrated packaging solutions are designed specifically around industry-specific requirements and are accompanied by application enabling software and vision capabilities. Yaskawa packaging systems bring ease of use, speed and flexibility to help you meet the demands of today’s food, beverage and consumer products marketplace.

For more information click Packaging Robot.

Palletizing

Yaskawa MOTORMAN offers manufacturers a wide range of robotic solutions for palletizing and depalletizing. When using flexible robotics with 2D and 3D vision systems, specialized software and tooling enable you to customize your shipping and receiving without sacrificing speed and accuracy.

For more information click Palletizing Robot.

Palletizing

Yaskawa MOTORMAN offers manufacturers a wide range of robotic solutions for palletizing and depalletizing. When using flexible robotics with 2D and 3D vision systems, specialized software and tooling enable you to customize your shipping and receiving without sacrificing speed and accuracy.

For more information click Palletizing Robot.

Painting

Yaskawa’s MOTOMAN robots continue to evolve as optimized robot in functions and performance of each application. The rich line up in the MOTOMAN-EPX series provides robots with variety of features for each type of work piece, arms with internally routed hoses and a high performance controller. The best robot for the application can be chosen to ensure high quality painting.

For more information click Painting Robot.